FORCE FOR CHANGE

Innovation and change management are essential instruments in a reality in constant transformation like ours. Therefore, Madrileña Red de Gas has assumed the commitment for enabling the creation of new opportunities in the gas sector that places the company at a referential position in the market.

We are aware that our professionals must be trained and able to communicate, transmit, make, and connect ideas with action facing new challenges, anticipating the change and generating a flow of knowledge based on experience, their strong points, and their professional and personal values.

Thanks to the innovation programmes started by the company in 2019, the MRG professionals are acquiring techniques for the implementation of new projects in which they can put into practice the acquired knowledge, like making a creative space or positioning in social networks.

Regarding change management, we have also developed the «Lead the change» course to prepare our professionals in the identification of opportunities and making them the natural generators of change.

Digitalisation is the ally of change and of innovation. Therefore, in MRG we have implemented new system tools aimed at attending to emergencies, telemetering management, and document management. During this year, we have trained out team in the use of «Power Bi», a new analysis tool for measuring operational ratios that is going to allow dynamically managing and sharing information with the users, as well as being able to simply visualise it in only one report. This way, all the information can be evaluated in a single report, according to the processed defined by MRG.

This year has closed with a total of 50 training actions and with more than 5,000 hours of training given (an average of 40 hours per employee).

TALENT

Talent management has continued being one of the MRG priorities. Our strategy is that our professionals become more efficient and productive and is centred on two lines of action: the so-called organisational humanisation, based on corporate culture that prioritises the wellbeing of persons, and collective leadership, focussing on the obtention of results through motivation and team commitment to marked projects and challenges.

In our recruitment processes we try to have professionals that are open to promoting their creative and innovative capacity as main driving forces for productivity and competitiveness; more empathetic, and committed team leaders that consider the person and the entire team when taking decisions, capable of dynamically recognising, understanding, and foreseeing changing situations and contexts.

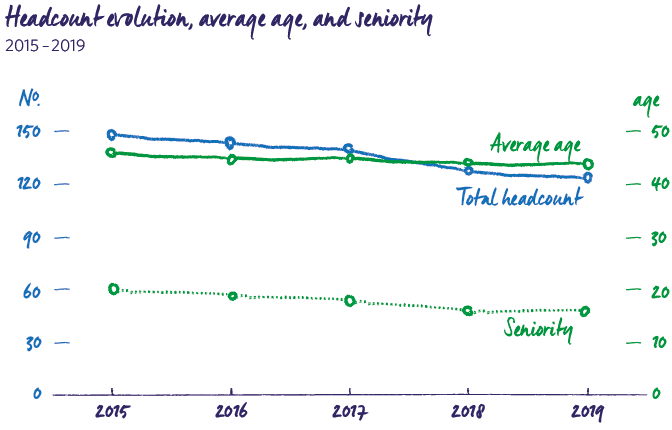

These changing contexts demand the generational renewal of the employees and the rejuvenating of our professionals, a process which MRG is progressively conducting, because we are aware that the mixture between the experience provided by veterans and the levels of competitiveness and innovation of youths results in better management of future challenges. That way, over the last five years, the average age of our professionals has decreased by 4%. In the year 2019 the average seniority decreased from 20 to 16 years.

The commitment for the dynamization and rejuvenation of our professionals has translated into 7% annual staff turnover, over the last five years, with an average age of 33.

In this year, seven new professionals have joined the MRG team, which represents 6% of the total headcount: 57% of these new hires are women. With exception of one administrative profile, the rest of new hires are graduates and engineers, with an average age of 36.

DIVERSITY

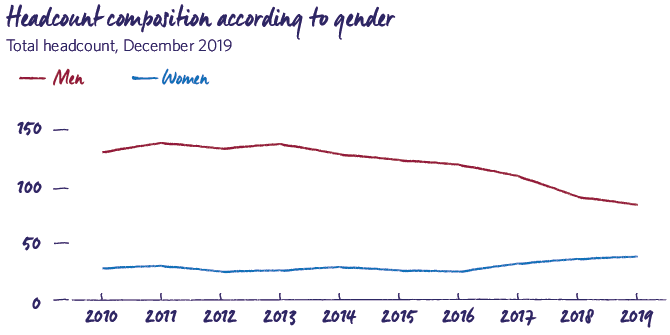

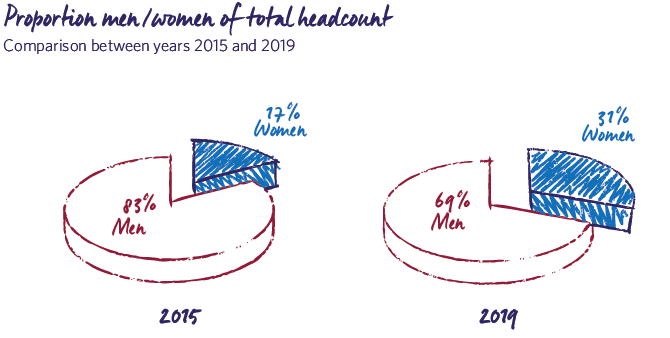

We know that commitment to gender diversity improves competitiveness of the companies and guarantees their sustainability, as well as providing another way of management. In MRG we want to be agents of change. Therefore, we put equality and diversity into value in our employment environment, promoting it from the bottom upwards with internal promotions, recruitment and training, same opportunities, and implementation of equality plans.

Regarding salary policies established by the company, the retribution will be equipped for all the professionals performing the same functions, focussing on retributions based on skills and objectives.

Every day we work to conduct fair and equal recruitment and promotion processes, in which gender is not a discrimination factor. When analysing the suitability of the candidates, we are strictly based on their professional profile.

Likewise, we promote female talent with training and mentoring programmes focussed on giving greater responsibilities and functions to women, to guarantee their professional growth and access to positions of greater responsibility and retribution.

Equally, our policies foster work-life balance, enabling the streamlining of working times, teleworking, and the approval of workday adaptations, both for men and women. This way, our professionals can deal with their responsibilities in the family. We also enable the reinstatement to the company after temporary periods of absence due to leave of absence, illness, or other circumstances.

EMPLOYMENT QUALITY

We have detected that our professionals were missing greater knowledge of the activities conducted in other areas of the company and greater feedback by the line managers

In MRG we understand human capital as the driving force of the company and the axis on which competitiveness and efficiency factors are sustained. Therefore, the adoption of measures that foster a good employment climate was a priority in 2019.

To evaluate the current situation and search for solutions to possible deficiencies that could be manifest in the employment environment, we have conducted a «climate survey». Thanks to this new initiative, we have detected that our professionals were missing greater knowledge of the activities conducted in other areas of the company and greater feedback by the line managers.

In response to this demand, and as a proof of the commitment by the entire structure of the company, from the human resources department, and with the collaboration of the Board of Directors, two projects aimed at covering these needs have been promoted:

Evolution

The directors of our business areas programmed different sessions aimed at bringing their staff closer to the different functions conducted in their departments, and the links these have with the rest of business activities. The sessions were a success of participation and evaluation by those who participated.

Connect

This project was launched to «connect» persons and processes based on a new focus in performance assessment. This way, our professionals who actively participate in the project, obtain six monthly feedback. Through these meetings, they agree their PDI with their managers, being able to establish aligned training plans that allow them to reach their objectives.

On the other hand, MRG actions in 2019 have also been aimed at creating a healthy environment and habits to our professionals that results in benefit for everyone.

Currently, there is a greater level of awareness about the importance of physical exercise. There are several reasons, from alleviating stress to losing weight, etcetera. Exercising is a great benefit for our health and improves life quality and our wellbeing both physically and psychologically. Therefor MRG, in addition to maintaining physiotherapy services and Pilates lessons, in 2019 we have created the Running club, where our professionals have a personal trainer who directs and focusses their training, to correct imbalances, avoid possible injuries and achieve good running techniques, all that accompanied by the use of tools and the application of the latest trends in the fitness world.

SAFETY AND RISK PREVENTION

The implementation of the Madrileña Red de Gas serious accidents prevention policy based on the Royal Decree 840/2015 (SEVESO III) regulating occupational accidents caused by hazardous substances is included in the «Safety management manual for prevention of serious accidents» and in the rest of procedures in which the management criterion for these very special assets must be applied.

In 2019, in the LPG plants all the necessary inspections have been completed with favourable results, in compliance with article 21 of the mentioned Royal Decree. Likewise, information has been provided to the DGI about the situation of these assets and the notifications of closing of the LPG installations for their detachment regarding the mentioned regulation. Also, we have reinforced the emergency plans by means of writing addenda, performing simulations, and giving specific training.

In 2019, in the LPG plants all the necessary inspections have been completed with favourable results, in compliance with article 21 of the Royal Decree 840/2015 (Seveso III). Also, we have reinforced the emergency plans by means of writing addenda, performing simulations, and giving specific training

In addition, in MRG we have implemented self-protection and emergency policies in the LPG plants with storage below 30 tons. We have also published and distributed the explosion protection documents (EPD) of the LPG plants, prioritising those affected by Royal Decree 393/2007, as well as by the Electro-technical low voltage regulation, and the perceptive visits for five-yearly inspections by OCA to the LPG plants have been made related to the mentioned regulation.

Likewise, we have carried out the monitoring of development of the improvement plan for safety conditions in the plants: periodical surveillance visits rounds, cameras, signage, perimetral fences of the installations, telecontrol systems (SCADA), etcetera, and the criterion related to connections between installations, safety valves, electrical installations, overfilling and cutting off systems. Also suitability evaluations have been made for the action procedures defined in the emergency and self-protection plans of the average size LPG plants, as well as new rounds of information sessions and emergency drills. The self-protection plans of the LPG plants have been revised and significant modifications have been made in the plants.

On the other hand, from among the diverse external protection service actions, we can highlight the start of the risk evaluation revision of the work centre, the periodical campaigns for medical health checks for the evaluation of personal risks of especially sensitive staff, and preventive notes.

Madrileña Red de Gas is still committed to cooperating with the competent authorities by remaining adhered to the «Bonus» system established by Royal Decree 231/2017. Once again, another dossier has been satisfactorily resolved with the subsequent reduction of the contributions for professional contingencies due to the contribution of MRG to the reduction and prevention of occupational accident rate.

Regarding to the transport of hazardous goods by road (ADR), the annual visits of the safety director to the LNG and LPG have been conducted, and the reports published extracting the necessary preventive and/or corrective measures. Also, the perceptive annual report has been prepared for the safety director for communication to the competent authority. Likewise, the internal regulation «PRL-833 – Safety management in the transport of hazardous goods» has been revised, new legislation and criteria have been included, training in the transport of hazardous goods by road has been given, and the procedures for unloading the LPG plants have been revised.

In relation to the policy of prevention of risks in activities with the potential presence of explosive atmospheres (ATEX), the implementation of these policies has been achieved in all the facilities. Likewise, different enquiries have been resolved related to the LIE detectors in the RMS and boiler rooms, the application criterion of the regulation in the scope of receiving installations, or the flame extinguisher devices.

At the headquarters of the company we have conducted business activities coordination actions regarding occupational risk prevention, because of several works for adaptation of the internal space, as well as the installation of solar panels on the roof of the building. On the other hand, an action criterion in situations of concurrence of our personnel with those of third parties has been established to the effects of adequate cooperation in occupational risk prevention.

Regarding the interchange of prevention documentation, performed through the external documentation control service, the mentioned service is monitoring document control of 133 contractor and subcontractor companies, as well as a thousand workers of the mentioned companies, with a volume in excess of 10,100 documents. Likewise, in 2019, MRG has continued to implement documentary exchange actions with new contracts, and the identification of the parameters and documentary requirements that are subject to supervision has been reviewed, such as those related to jobs with electrical hazards.

These documentary controls are completed through direct supervision in the field, which was already started in previous years, through which the effective application of a large number of preventive measures and the documentation provided are checked in order for them to be correct. The result of these visits to supervise activity is communicated to the MRG contractors for their knowledge and implementation of improvements. In a complementary manner, periodic follow-up meetings are held with the supervisors in the field to promote the usual dialogue with the prevention technicians of the main contractors and establish effective communication channels. In all, there have been nearly 244 operational control visits, distributed among the entire range of relevant activities.

True to its policy of giving occupational risk prevention information to interested parties, MRG has continued improving the content available in its prevention information channel, allowing access to both company workers and to our extended company, so that access to the updated editions of the occupational risk prevention information is guaranteed.

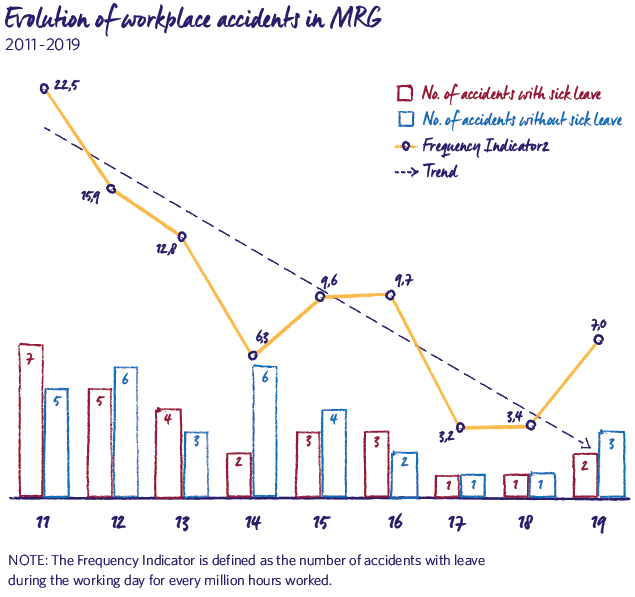

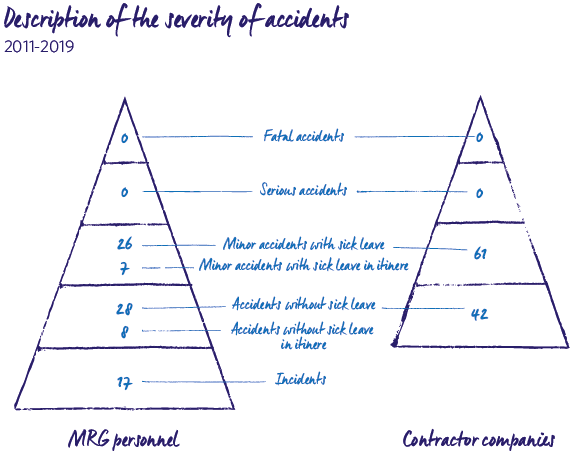

In January 2019, and for the second time in our history, we reached the milestone of 12 consecutive months without accidents with sick leave not while travelling. Later, two occupational accidents not while travelling with sick leave, and three accidents not while travelling without sick leave have been reported, which has caused an increase in the frequency index.

Regarding personal protection equipment (PPE), collective protection and clothing, we have continued with the good practice of periodical external revision of the rescue tripods, the safety harnesses, and other elements of this group. Likewise, we maintain direct communication with our normal equipment and materials suppliers, which facilitates access to the information about new equipment and materials arriving on the market.

For activities that involve the execution of construction works, periodic monitoring of the health and safety managers’ activity is conducted. In 2019, the use of preventive management documentation has been extended for the works without projects and there have been meetings of the Health and safety committee, following up the most relevant subjects related to occupational risk prevention.

Finally, the development of quality management during this year has been characterised by the focus applied to the improvement of processes, in addition to continuing with transition project of the quality management system to adapt it to the requirements of the new revision of the ISO 9001:2015 standard.

Also, the management model of steel networks has been revised, identifying opportunities for improvement regarding the certification of materials, supervision figure in the welding process, and authorisation of the participating personnel. Likewise, the management model for assets with electrical supply has been revised and improvements related to the minimum requirements to be applied in the different existing scenarios, specific training of our personnel, and the complete renewal of electrical installations have been established.

In 2019 we have also developed a self-protection and emergency model defining the policies that must be applied in small size gas storage centres, and in the regulation stations of the gas distribution network

Regarding the quality system according to the ISO 9001:2015 standard, we have updated the quality indicators, focussing attention on the most relevant parameters of critical processes. Likewise, development of the «processes map» has continued from the quality perspective, increasing the initial two level focus to three. Level 1 shows the complete photograph of the processes, while level 2 gives a description of each numbered process in greater detail; level 3 identifies those in charge of the processes and the most outstanding regulatory requirements. This processes map offers a more transversal and in-depth view of the most essential activities of the company.

On the other hand, the environment and scope of the regulation updating services have been revised to adapt them to the needs of the company.

INTEGRATED MANAGEMENT SYSTEM

The activities conducted in the MRG risk management area during this year have been aimed at continuing the project for adapting the prevention, environment, and quality managements to the ISO 45001:2018, ISO 14001:2015, and ISO 9001:2015 respectively. The content of different internal regulations of the integrated management system and the internal auditing procedures and training has been revised.

Likewise, all the inspections of article 21 of Royal Decree 840/2015 SEVESO in the LPG plants have finalised, with favourable results, that way completing a first cycle of inspections. Also, many documents for protection against explosions in LPG storage centres have been prepared, as well as the processing of preliminary and closing reports of contaminated ground of the mentioned storage centres.

In 2019 we have also developed a self-protection and emergency model defining the policies that must be applied in small size gas storage centres, and in the regulation stations of the gas distribution network. To estimate the fugitive emissions of methane from the distribution network, we have opted for a methodology by events and the adaptation of the control panel and indicators of quality management has been adapted to the needs of the organisation and the improvement of processes related to management of steel networks and assets with electricity supply.

In 2019 we have also developed a self-protection and emergency model defining the policies that must be applied in small size gas storage centres, and in the regulation stations of the gas distribution network

Likewise, an analysis of the series of UNE-CEN TS 15399EX and PNE-EN 15399 standards, with the objective of planning the addition to our management system of those good practices linked to the gas sector.

On the other hand, to parameterise and digitally develop the processes related to the integrated management system for prevention, environment, and quality, we have used the «Incaweb» management tool, which is being adapted to the needs of the company, with the development of operational control visits and reports from the directors for the safety of hazardous goods transport. Even in the partial implementation phase, the tool has already been used in several management system processes, like the objectives of the system, the planning of inspections, or the corrective actions.